Properties of Velmex Linear Stages

Linear Slide Orientation

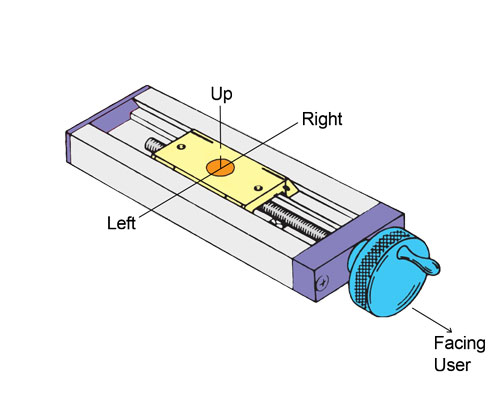

The reference points for determining the orientation of any Velmex linear stage (UniSlide®, BiSlide® or XSlide™) are: the base down, the carriage up, and the knob or motor facing the user. When referencing the horizontal position (X axis), this the orientation being used.

The reference points for determining the orientation of any Velmex linear stage (UniSlide®, BiSlide® or XSlide™) are: the base down, the carriage up, and the knob or motor facing the user. When referencing the horizontal position (X axis), this the orientation being used.

When referencing an inverted position, it is the opposite. The base is up and the carriage is down.

When referencing a vertical position, the stage is on its end and the carriage travels up and down. Either end of the stage can be on the bottom or the top. However, there might be different load parameters, depending on whether the knob or the motor is located at the top or at the bottom. See the definition of "Lift" and "Thrust" on the Load Parameters Page.

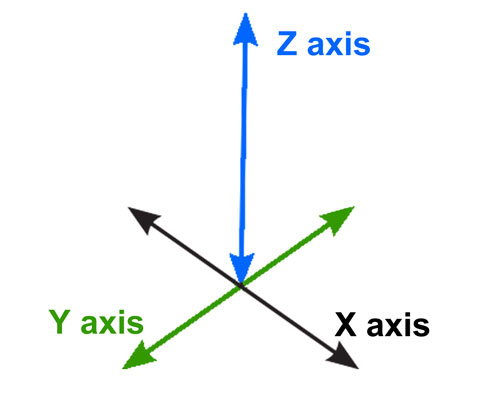

As a standard, we use the machine tool coordinate designations where 'X' is the bottom horizontal axis, 'Y' crosses the 'X' at 90 degrees and is also in the horizontal plane, and the 'Z' axis runs vertically (perpendicular) to the 'X' or 'Y' axis.

As a standard, we use the machine tool coordinate designations where 'X' is the bottom horizontal axis, 'Y' crosses the 'X' at 90 degrees and is also in the horizontal plane, and the 'Z' axis runs vertically (perpendicular) to the 'X' or 'Y' axis.

- Option Positioning

The Rapid Advance control lever is mounted on the right hand side of the unit. Printed and engraved scales are on the left side. (Refer to the image above.) Scale numbering progresses toward the knob end of the unit. Scales, verniers, rapid advance control levers, locks, etc. can be mounted opposite of the standard, on request. Note: There would be a slight loss of travel distance with the vernier mounted on the opposite side of the standard location.

Composition

The primary composition of all Velmex Positioning Stages is an aluminum alloy. An aluminum extrusion is the basis for all linear stages – UniSlide™, BiSlide™ and XSlide® Assemblies.

Additional components including lead screw, carriage, drive nut, bearing pads, etc. may contain minimal amounts of one or more of the following materials: brass, nickel, steel, Rulon® 123, Delrin® acetal homopolymer resin and Delrin AF.

Material substitutions can be made to address specific applications including operating in a vacuum. See Vacuum Applications.

Straightness

The straightness tolerance of the extrusion is half the normal commercial tolerance. Precision machining and tapping the dovetail ways deliver a high degree of straightness and parallelism.

All Velmex linear assemblies are individually selected, measured and certified for straightness.

- Deviations from Straightness - UniSlide Assemblies

For example: UniSlide Assemblies are machined by Velmex. Their deviations from straightness, measured at the upper limits as determined by our manufacturing processes, are:

• Bow* |

< 0.002" per foot (0.05 mm per 305 mm) (deviation in the upward direction) |

|---|---|

• Run Out |

< 0.001" per foot ( 0.025 mm per 300 mm) (deviation in the horizontal direction) |

• Twist |

1 milliradian per foot (a twist in the direction of the slide) |

*Bow can be affected by the degree of flatness of the supporting surface and the relative tension of the mounting screws, once the stage is installed.

- Deviations from Straightness - BiSlide Assemblies

BiSlide Assemblies are manufactured from extrusions. The deviation from straightness is measured at 0.003" (0.076 mm) over the entire travel distance.

- Deviations from Straightness - XSlide Assemblies

XSlide Assemblies are manufactured from extrusions. The deviation from straightness is measured at 0.001"/10" (0.025mm/25cm).

- Enhanced Tolerances

If your application requires tighter straightness tolerances, we can supply models with straightness tolerances approximately one-half of the nominal values above.

Load Calculations/Capacities

Please see the page that defines load capacities of Velmex stages and how to calculate them. Or review the specifications on the particular product page.

Wear Resistance

Our aluminum alloy dovetail base and low friction polymer pads on the carriage deliver excellent bearing performance and reduce erosion and wear. |

|

|

|---|---|---|

Unlike ball screw slide mechanisms, no lubrication is required. |

||

Wear measurements for sideways play under light to moderate loads: |

||

First 30,000 cycles of operation |

- approximately 0.00015 inches. |

|

Next 50,000 cycles of operation |

- wear will be reduced, to approximately 0.00005 inches |

|

The carriages on our linear stages are equipped with adjustment screws to compensate for wear, if necessary. UniSlides and XSlides can be easily adjusted, although it should be rarely needed. Because of the interlocking design and the assembly process for BiSlide stages wear adjustment is a little more problematic to accomplish. Refer to the slide's User's Manual. |

||

Harsh Environments and Specialty Applications

For harsh environments and/or a higher number of cycles, assemblies with hard coat anodized ways are available. For clean room environments, we recommend electroless nickel plating.

- Vacuum Applications

Use Velmex Assemblies in a myriad number of environments from outer space to vacuum chambers. We modify the stages to meet a vacuum's stringent requirements. However, for critical applications cycle the assemblies in an outgassing chamber to remove residual contamination. See Vacuum Applications for detailed information.

Other Specialty and Custom Applications

Material substitutions can also be made for specific applications. See the "Material Substitution" section at the bottom of Vacuum Applications for detailed information on substitutions.

- Magnetic Properties

We can produce linear positioners with very low or no ferric (iron) content. The base and carriage assemblies are made from aluminum alloy. Most lead screws for UniSlide and XSlide Assemblies are 303 stainless steel.

The exceptions are the double and quad lead screws which are electroless nickel-plated cold rolled steel. BiSlide Assembles lead screws are primarily the electroless nickel-plated cold rolled steel. One BiSlide lead screw is stainless (M01 - pitch = 10 turns per cm/1 cm per revolution)

Material substitutions for drive nuts and thrust bearings/bushings are also available. See the "Material Substitution" section at the bottom of Velmex Products in a Vacuum for detailed information on substitutions or contact the factory.

- Sizes and Options

A myriad of options and accessories are available to build custom systems to your specific requirements. They include:

A myriad of options and accessories are available to build custom systems to your specific requirements. They include:

• Non-standard base/travel lengths.

• Alternative carriage lengths. See the options chart under each brand.

• Alternative knobs including cranks, graduated knobs and rogan knobs.

• Adapter plates, brackets, gussets and frames.

• Various locks

• Revolution counters and encoders

• Left / Right lead screws

• Angled gearboxes

• Scales, verniers, rapid advance control levers, locks, etc. can be mounted opposite of the standard, on request.